Thin film deposition techniques have been developed with semiconductor device manufacturing techniques, and are applied to very many fields today.

Deposition technique of the thin films with new function on the existing objects (such as corrosion-resistant coating on precision parts, wear-resistant coating on automobile parts and cutting tools, gas-barrier coating on food packaging resin etc.) generates additional values.

Application range of thin film deposition technique will continue to increase in the future.

JAC are providing consistent service such as:

- Selection (synthesis/purification) of appropriate precursor to meet customer’s requests.

- Film deposition test.

- Provide immediate feedback.

- Screening of precursors.

- Development of basic deposition process.

Based on the customer’s needs, we will offer the appropriate precursors and processes, and will perform film deposition test.

✔ You want to check the film characteristics and deposition condition as a trial?

✔ You want to find out appropriate system design, required modification, film deposition conditions etc. before establish new project?

Do you worry about following situations?

✔ Introducing new precursors entails high risk and existing system can’t be used.

✔ It will take too much time to prepare new system/environment for preliminary assessment.

We can solve your problems.

In order to provide solution to such situations, we prepared necessary and sufficient environment in which you can try film deposition test using new precursors, and can determine optimum precursor by screening, and can evaluate new process freely, with necessary assistance by our expert staff.

Doing the preliminary film deposition test and precursor screening in our laboratory, you may be able to reduce the cost and shorten the development period drastically.

In response to requests from customers, we can modify our system, and change the settings flexibly such as:

- Gas line

- Heating method

- Plasma treatment

- Providing bias in wafer …etc.

Please feel free to consult us.

We are fully prepared to help you at any time.

Ar Gas

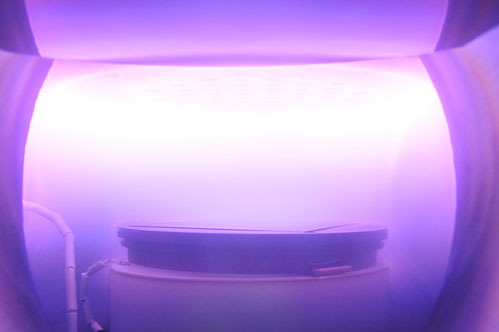

Plasma treatment based on Ar gas.

H2 Gas

Reduction treatment with H2 gas.

SF6 Gas

Cleaning of the chamber with SF6 gas.

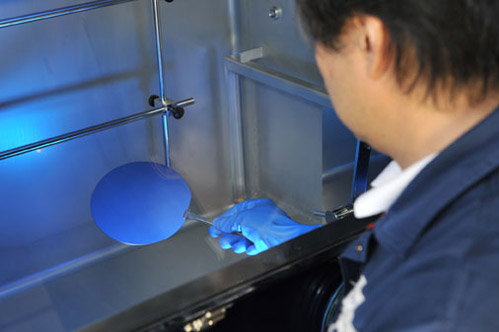

Wafer treatment (G-Box)

Wafer treatment in the nitrogen environment.

Items that can be studied in film deposition test (example)

【Precursor】

Precursor structure, bottle shape, vaporization temperature, gas flow rate, carrier gas flow rate, precursor stability etc.

【Gas】

Appropriate oxidizing gas, appropriate nitriding gas, its flow rate etc.

【System】

Film deposition temperature, chamber pressure, film deposition process, wafer dependency, embedding properties etc.

You can obtain chemical property information of the precursor (including thermal stability, decomposition temperature, vapor pressure etc.), and also can embody the optimum system specification clearly based on the result of actual film deposition tests using the precursors.

Our systems are prepared for various oxidizing agent such as H2O, O2, high-concentrated ozone (over 500g/m3) and N2O etc., depending on your request.

NH3 can be used as reductant of nitriding gas.

| UHV type CVD, ALD system | High-temperature CVD・ALD system | Hot wall CVD, ALD system |

|---|---|---|

|

|

Simple evaluation system and can be heated up to 650 deg-C. The precursors which have lower vapor pressure can be handled in this system. |

| UHV type CVD/ALD system for evaluation of precursors/processes. It has 12 gas lines, and extra line can be installed upon request. |

High-temperature CVD/ALD system for evaluation of precursors/processes. It can be heated up to 1,000 deg-C. |

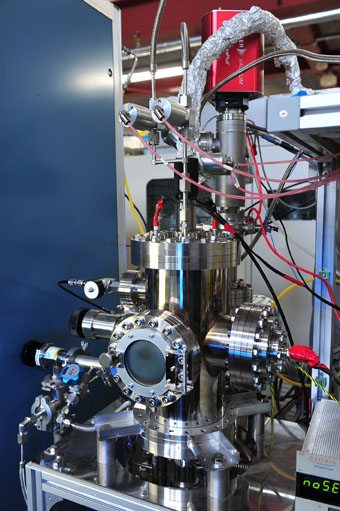

UHV type CVD・ALD system

| Specification | Ultrahigh vacuum load lock type (Pump: TMP・MBP・RP) |

|---|---|

| Stage temperature | ~500℃ |

| Gas/Precursor line | 4 lines + carrier gas and dilution gas (total 12 lines) |

| Precursors | Si, Al, Ta, Hf, Pt, Ni, Co etc. (various organic metals) |

| Oxidation gas | H2O, O2, high-concentrated Ozone, N2O etc. |

| Reduction gas | H2, NH3 |

| Exhaust gas | treatment Scrubber |

| Feature |

Parallel-plate plasma (RF power supply:13.56MHz/1.5KW). Gas line can be changed. Extra line can be installed. ALD sequence can be changed. ICP can be installed. When install ICP on L/L, pretreatment is possible. |

High-temperature CVD・ALD system

| Specification | Ultrahigh vacuum type (Pump: TMP・MBP・RP) |

|---|---|

| Stage temperature | ~1000℃ |

| Gas/Precursor line | 2 lines + carrier gas and dilution gas |

| Precursors | Si, B etc. (for high-temperature application) |

| Oxidation gas | NA |

| Reduction gas | NH3 |

| Exhaust gas | treatment Scrubber |

| Feature | Extra line can be installed. ALD sequence can be changed. Q-MS measurement in exhaust line is possible. |

Hot wall CVD, ALD system

| Specification | Simple Hot wall CVD, ALD system |

|---|---|

| Stage temperature | ~650℃ |

| Gas/Precursor line | Please contact us |

| Precursors | Please contact us |

| Oxidation gas | H2O, O2, O3, N2O |

| Reduction gas | NH3 |

| Exhaust gas | treatment Scrubber |

| 備考 | JAC社製簡易成膜装置 |